Heat exchange equipment is widely used in the oil and gas and chemical industries for technological operations in which it is required to maintain a predetermined operating temperature.

TH SARRZ supplies heat exchangers of various types directly from manufacturers that allows us to complete Your facility with the most suitable equipment.

The need for the use of industrial heat exchange equipment is on the the requirements of operating procedure at the facility. Many process parameter, for example, process reaction rate, chemical reaction intensification, etc., depend on the operating temperature requirements (hot and cooling processes). If the processes result in heat release, it should be recovered with technological and economic benefits.

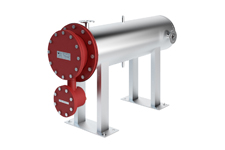

Heat exchangers can be of different designs depending on their application, operating procedure specifics, the properties of the working medium, its speed and time spent in the apparatus, the operating pressure, as well as the requirements for the operating temperature and the possibility of its regulation.

Classification of heat exchange equipment is based on various characteristics:

The principle of action of the heat exchange equipment is the heat exchange between the heat-transfer medium and the processing medium. The heat-transfer medium can be water, saturated steam, oil, warmed gas or air. When choosing a heat-transfer medium, the temperature limits and the maximum possible pressure in the system are taken into account. Heat-transfer fluid and steam have a maximum heating temperature of +150-160°C and a pressure of up to 0.7 MPa. When using oil temperature can reach 200°C. The maximum heating (300-1000°C) is achieved with warmed gases or air.

Depending on the type of heat-transfer medium and structural design of the heat exchange tank, the former may circulate through the pipes and shell side, plates, between the shells of the inner vessel and outer casing, through the grids, etc.

For the optimal choice of the heat exchanger in compliance with the requirements to its pressure resistance, as well as its material and design, heat exchanger thermal design is carried out to obtain the maximum efficiency at minimum heat energy costs and heat-transfer efficiency increase.

| № | Criteria | Value |

|---|---|---|

| 1 | Operating pressure, MPa | 0.6-8.0 |

| 2 | Diameter, mm | 150-1400 |

| 3 | Heat exchange surface area, m2 | up to 1000 |

| 4 | Apparatus length, mm | 11500 |

| 5 | Heat-transfer medium temperature, °С | up to +450 |

| 6 | Seismic activity in the area of construction, points | up to 7 |

| 7 | Climatic category | N, NF, Т |

| 8 | Property class | 1, 2, 3 |